Early detection of product issues can be the difference between a project’s success or failure. When it comes to verifying the quality of workmanship or the actual operating conditions, our highly skilled Test Team carries out testing regimes on-site and under real-world conditions.

Testing in a real-world landscape, helps us to understand if the product, material or system operated according to its intended design criteria.

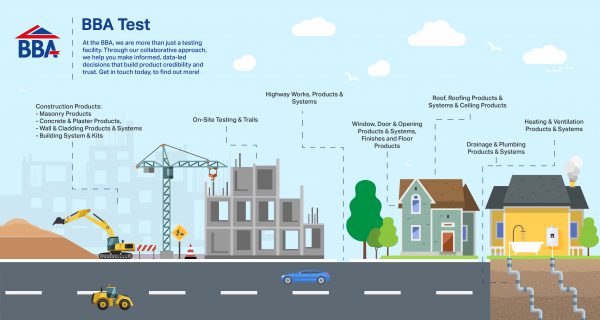

The BBA’s Test facilities allow us to provide a comprehensive range of services covering a wide variety of products from; insulation materials and systems to windows and doors, sealants and adhesives, flooring materials and structural components.

We measure product performance across:

- Transportation

- Storage

- Handling

- Installation

- Fabrication

- Disposal stages

Products are also verified and compared against traditional or alternative methods and solutions – this gives a complete overview.

Our field technicians, engineers and support staff are qualified to test construction materials and systems on site, ensuring the quality of workmanship, materials, and that proper installation practices are employed for each project.

What tests do we offer?

- Pull out of fixings

- Shear testing on fixings

- Load testing

- Point load

- Linear load

- Uniformly distributed load (UDL)

- Flexural (and dead load) testing

- Pull through testing

- Sampling

- Coring

- Cover-meter (with load test and inspection)

- Security testing (only manual “breaking in”)

- Slip resistance/pendulum tests

- Trials

- Process characterisation/mapping for mock up tests at laboratory

- Studies and assessments

- Time/motion

- Transportation, storage and handling

- Waste production

- Environmental noise and thermal performance

- Dimensional and tooling requirements

“The service we are receiving from the test department is really good. Paul has been amazing and really helpful”

– Efosa, Sundolitt – United Kingdom

Get in touch

To enable us to respond to your inquiry as soon as possible, please select from the drop-down list in the box below and then complete the relevant form.

If you are unsure which service you require, you can find a handy reminder below the box.