British Board of Agrément Selected to Certify Innovative Start-Up AirEx’s First-to-Market Energy-Saving Smart Air Brick

AirEx, an innovative manufacturer that was founded in 2017, recently chose the BBA to work with to obtain a third-party Agrément certification for its unique and first-of-its-kind, smart air brick solution. The BBA was chosen due to its high regard, thorough due diligence and recognition within the industry. Designed to help regulate airflow and reduce energy demand, the smart air brick effectively saves costs and provides draught-proofing while managing moisture levels within residential properties.

The founder of AirEx, Agnes Czako, who has a background in sustainable building design and the delivery of thousands of energy assessments for social housing providers, saw a gap in the market for a robust, sustainable, inexpensive and simple solution to more easily retrofit homes in the social housing sector affected with ventilation, damp and mould issues.

Agnes who worked closely with the team at the BBA during the certification process explained, “We found working with the BBA invaluable and appreciated their approach to certifying an innovative product. Although the process was longer than initially anticipated and more rigorous, we ended up with a robust product that is now certified as fit for purpose. It can now be specified and deployed at scale for large social housing projects and complies with the requirements for government and industry-supported fuel poverty and decarbonisation schemes.”

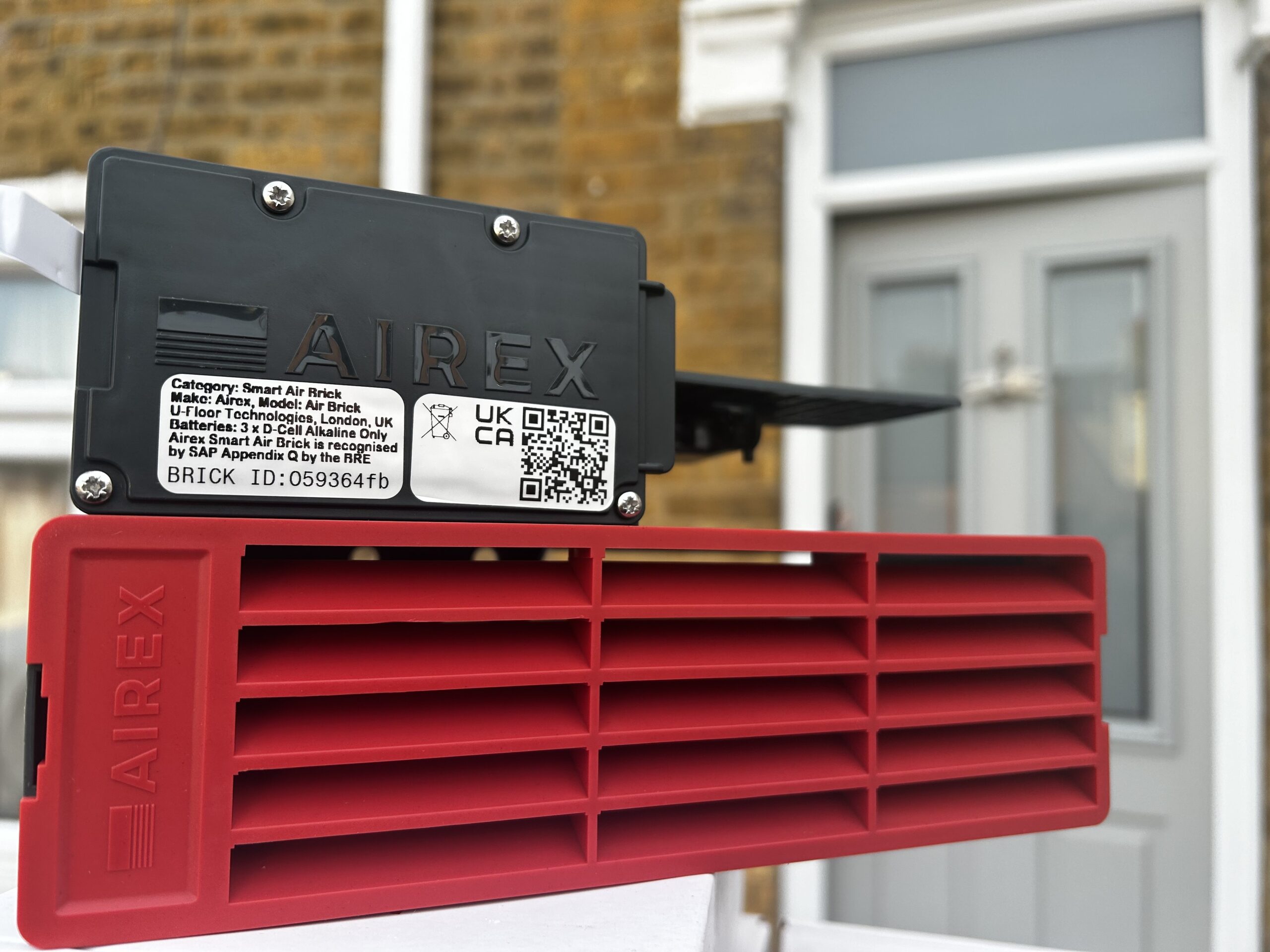

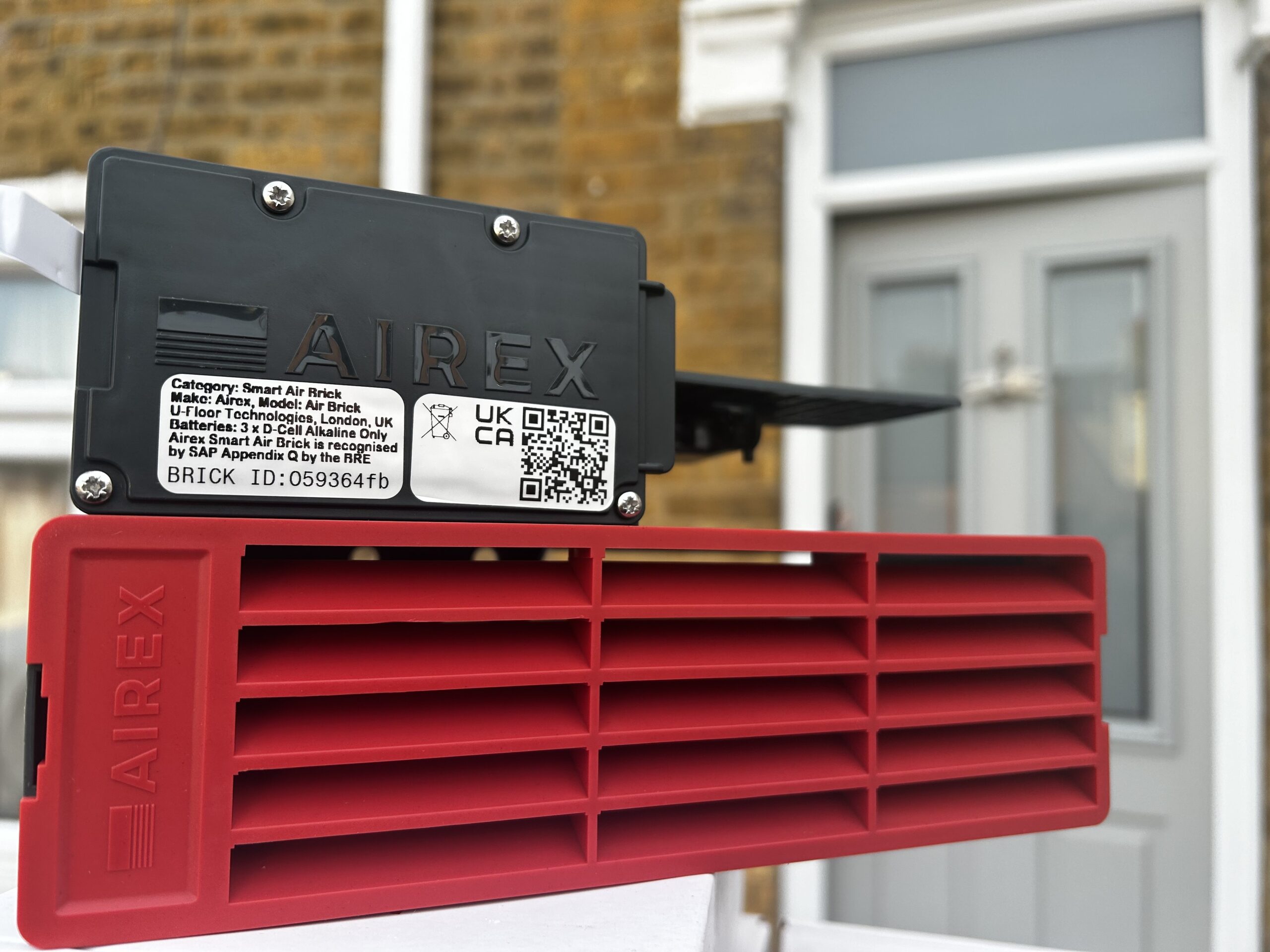

The unique smart air brick solution by AirEx was created to provide a solution to not only help with the ventilation of domestic properties, but to save on energy consumption and costs. The solution comprises of a ventilator with a motor-driven flap that is controlled by a home hub, which monitors humidity and regulates airflow to reduce energy demand and provide draught proofing. The product is suitable for all residential properties that have a suspended ground floor. The AirEx air brick is simple, quick and straight forward to install plus can improve the EPC rating of a home and save the homeowner or tenant energy costs.

The patented factory-engineered AirEx solution provides an effective, simple and durable solution. As industry trailblazers, AirEx created a novel innovation with the air brick, which did at first create a challenge, as the BBA had no similar products to benchmark and compare against. To overcome this, the BBA set new standards using existing products which closely resembled the air brick. Whilst the additional analysis meant it took longer than usual for the process, the BBA was committed to adhering to its rigorous processes and championing innovation and continuing to maintain its stringent testing protocols.

The Certification Process

The team at AirEx began the certification process with the BBA in 2022, having already achieved third-party verification of the product’s energy-saving capabilities through the Building Research Establishment (BRE). AirEx then pursued third-party certification by the BBA to verify the product’s quality, safety and technical compliance, in addition to its procurement procedures and processes. BBA certification also ensures that the product can be specified and maintained in large government funded projects, such as the Social Housing Decarbonisation Fund (SHDF) and Home Upgrade Grant (HUG), and meets the requirements of the large industry-funded ECO (Energy Company Obligation) fuel-poverty scheme. Through expert guidance and working in collaboration with the BBA and the rigorous certification process, the team at AirEx received factory visits to help refine and improve the product’s procedures for production. The BBA team also visited customers and reviewed the installation process to ensure the overall safety and quality assurance of the product was being adhered to ensure robustness and sustainability.

Chris Stobart, AirEx’s Chief Technology Officer, who led to process on behalf of AirEx, added, “Our whole team feels proud to have worked with the BBA to achieve an Agrément certificate for our unique product. Securing an Agrément certificate is a highly demanding and rigorous process for any company, and even more so for a start-up. The team has worked incredibly hard to reach this point, so we feel great about achieving this milestone of our first certificate.”

Conclusion

Katy Roberts, BBA Sales & Marketing Director, stated, “This project showcases the BBA’s capability to support and certify innovative products and establish new industry standards if not already in existence. The BBA Agrément Certificate proves that AirEx’s smart Air Brick meets UK building and safety regulations, making it a reliable and compliant option for contractors retrofitting homes, enhancing energy efficiency across the UK.”

Agnes Czako further added, “The BBA Agrément Certificate demonstrates that we can provide our customers with the assurance of our product’s performance and compliance with Building Regulations and the requirements of PAS2035/30. This is a game-changer for us in terms of growth for the product, as this enables its use for larger housebuilders, installers, warranty providers and government-funded programmes. To have BBA certification demonstrates that our products have been tested to the highest standards expected here in the UK and confirms the energy-saving performance. This is an exciting milestone in our mission to address fuel poverty and decarbonisation as it will provide confidence to our customers to deploy AirEx at scale.”

As a trailblazer in the space, AirEx has helped open the door for other innovators applying for certification with the BBA, which has continued to implement changes since AirEx first began the process. Gaining certification with the BBA has acted as a significant trigger in AirEx achieving government funding, meaning vital subsidised social housing projects can utilise the Air Brick for a quick and cost-effective solution.

Maintaining the certification throughout the product’s lifecycle, and working collaboratively with the BBA, will provide AirEx with a greater insight into changing industry regulations, which AirEx can appropriately apply to its processes to help provide essential product confidence and credibility for its products in the social housing sector.

The BBA Agrément Certificate is a gold standard in the UK construction industry. It establishes suitability and builds trust. Throughout the whole construction supply chain, BBA certificates are used to authenticate and specify suppliers for construction projects. Being certified opens up opportunities for those bringing a new product to market, or sets an existing product apart from its competition.

Share This Story, Choose Your Platform!

Related News

British Board of Agrément Selected to Certify Innovative Start-Up AirEx’s First-to-Market Energy-Saving Smart Air Brick

AirEx, an innovative manufacturer that was founded in 2017, recently chose the BBA to work with to obtain a third-party Agrément certification for its unique and first-of-its-kind, smart air brick solution. The BBA was chosen due to its high regard, thorough due diligence and recognition within the industry. Designed to help regulate airflow and reduce energy demand, the smart air brick effectively saves costs and provides draught-proofing while managing moisture levels within residential properties.

The founder of AirEx, Agnes Czako, who has a background in sustainable building design and the delivery of thousands of energy assessments for social housing providers, saw a gap in the market for a robust, sustainable, inexpensive and simple solution to more easily retrofit homes in the social housing sector affected with ventilation, damp and mould issues.

Agnes who worked closely with the team at the BBA during the certification process explained, “We found working with the BBA invaluable and appreciated their approach to certifying an innovative product. Although the process was longer than initially anticipated and more rigorous, we ended up with a robust product that is now certified as fit for purpose. It can now be specified and deployed at scale for large social housing projects and complies with the requirements for government and industry-supported fuel poverty and decarbonisation schemes.”

The unique smart air brick solution by AirEx was created to provide a solution to not only help with the ventilation of domestic properties, but to save on energy consumption and costs. The solution comprises of a ventilator with a motor-driven flap that is controlled by a home hub, which monitors humidity and regulates airflow to reduce energy demand and provide draught proofing. The product is suitable for all residential properties that have a suspended ground floor. The AirEx air brick is simple, quick and straight forward to install plus can improve the EPC rating of a home and save the homeowner or tenant energy costs.

The patented factory-engineered AirEx solution provides an effective, simple and durable solution. As industry trailblazers, AirEx created a novel innovation with the air brick, which did at first create a challenge, as the BBA had no similar products to benchmark and compare against. To overcome this, the BBA set new standards using existing products which closely resembled the air brick. Whilst the additional analysis meant it took longer than usual for the process, the BBA was committed to adhering to its rigorous processes and championing innovation and continuing to maintain its stringent testing protocols.

The Certification Process

The team at AirEx began the certification process with the BBA in 2022, having already achieved third-party verification of the product’s energy-saving capabilities through the Building Research Establishment (BRE). AirEx then pursued third-party certification by the BBA to verify the product’s quality, safety and technical compliance, in addition to its procurement procedures and processes. BBA certification also ensures that the product can be specified and maintained in large government funded projects, such as the Social Housing Decarbonisation Fund (SHDF) and Home Upgrade Grant (HUG), and meets the requirements of the large industry-funded ECO (Energy Company Obligation) fuel-poverty scheme. Through expert guidance and working in collaboration with the BBA and the rigorous certification process, the team at AirEx received factory visits to help refine and improve the product’s procedures for production. The BBA team also visited customers and reviewed the installation process to ensure the overall safety and quality assurance of the product was being adhered to ensure robustness and sustainability.

Chris Stobart, AirEx’s Chief Technology Officer, who led to process on behalf of AirEx, added, “Our whole team feels proud to have worked with the BBA to achieve an Agrément certificate for our unique product. Securing an Agrément certificate is a highly demanding and rigorous process for any company, and even more so for a start-up. The team has worked incredibly hard to reach this point, so we feel great about achieving this milestone of our first certificate.”

Conclusion

Katy Roberts, BBA Sales & Marketing Director, stated, “This project showcases the BBA’s capability to support and certify innovative products and establish new industry standards if not already in existence. The BBA Agrément Certificate proves that AirEx’s smart Air Brick meets UK building and safety regulations, making it a reliable and compliant option for contractors retrofitting homes, enhancing energy efficiency across the UK.”

Agnes Czako further added, “The BBA Agrément Certificate demonstrates that we can provide our customers with the assurance of our product’s performance and compliance with Building Regulations and the requirements of PAS2035/30. This is a game-changer for us in terms of growth for the product, as this enables its use for larger housebuilders, installers, warranty providers and government-funded programmes. To have BBA certification demonstrates that our products have been tested to the highest standards expected here in the UK and confirms the energy-saving performance. This is an exciting milestone in our mission to address fuel poverty and decarbonisation as it will provide confidence to our customers to deploy AirEx at scale.”

As a trailblazer in the space, AirEx has helped open the door for other innovators applying for certification with the BBA, which has continued to implement changes since AirEx first began the process. Gaining certification with the BBA has acted as a significant trigger in AirEx achieving government funding, meaning vital subsidised social housing projects can utilise the Air Brick for a quick and cost-effective solution.

Maintaining the certification throughout the product’s lifecycle, and working collaboratively with the BBA, will provide AirEx with a greater insight into changing industry regulations, which AirEx can appropriately apply to its processes to help provide essential product confidence and credibility for its products in the social housing sector.

The BBA Agrément Certificate is a gold standard in the UK construction industry. It establishes suitability and builds trust. Throughout the whole construction supply chain, BBA certificates are used to authenticate and specify suppliers for construction projects. Being certified opens up opportunities for those bringing a new product to market, or sets an existing product apart from its competition.

Share This Story, Choose Your Platform!

Related News

Get in touch

Please complete the form below and we will contact you as soon as possible.

To help us to respond to your inquiry as quickly as possible, we have put a handy list of our services below.